How Do You Track Inventory Across Multiple Locations Without Stockouts or Overstocking?

Real-time inventory tracking across all warehouses and sales channels. Prevent stockouts with automated reorder points, eliminate overstocking with accurate demand forecasting, track lot and serial numbers for traceability, and sync inventory with orders, manufacturing, and accounting automatically in one unified system.

Most businesses track inventory using spreadsheets, manual stock counts, and disconnected systems for each warehouse location. Inventory counts are inaccurate, stockouts happen unexpectedly, overstocking ties up cash, and reconciling inventory between warehouses requires manual effort. Alpide Inventory Management provides real-time visibility across all locations. When items are sold, received, transferred, or manufactured, inventory updates automatically. Reorder points trigger purchase requisitions when stock runs low. Lot and serial tracking provides complete traceability. Multi-location inventory balances show exactly where products are located—eliminating manual stock counts, preventing stockouts, and reducing excess inventory caused by poor visibility.

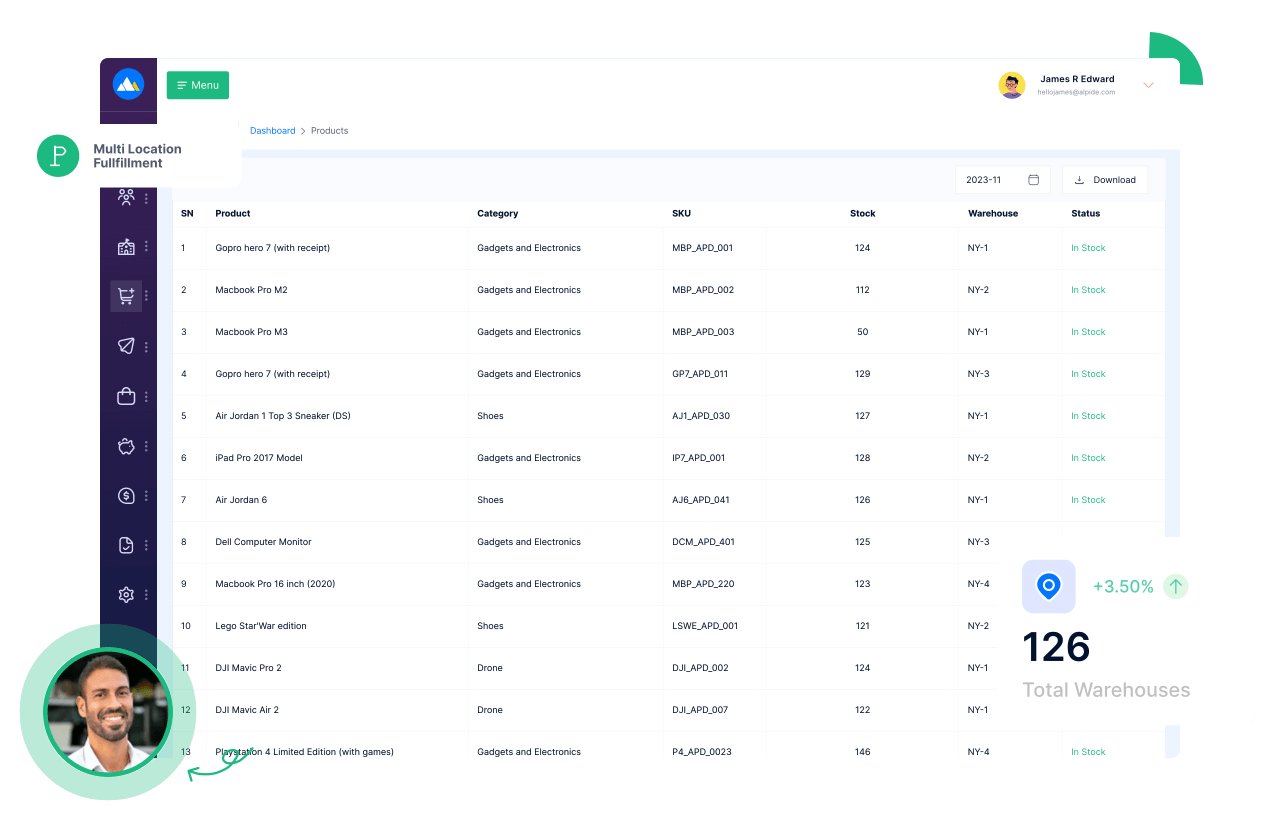

Complete Multi-Location Inventory Control

Track inventory levels across all warehouse locations, retail stores, and third-party fulfillment centers in real-time. Manage stock movements including receipts, sales, transfers, adjustments, and returns. Automate reorder points to prevent stockouts, track lot and serial numbers for traceability, value inventory using FIFO, LIFO, or weighted average methods, and synchronize inventory with order management, purchasing, manufacturing, and accounting. Real-time visibility into stock levels, locations, and movements enables better inventory decisions and reduces carrying costs.

Automated Real-Time Inventory Updates

Inventory updates automatically when orders ship, purchases are received, items are transferred between locations, or production consumes materials. No manual inventory adjustments needed after each transaction. Barcode scanning during receiving and shipping ensures accuracy. Real-time stock levels prevent overselling and stockouts. Automated inventory synchronization eliminates manual stock counting and reconciliation between systems.

Multi-Location Inventory Visibility

View inventory levels across all warehouse locations from one dashboard. See exactly how many units are available at each location, in-transit between warehouses, reserved for pending orders, and available to promise customers. Route orders to the closest warehouse with available inventory for faster shipping. Transfer stock between locations to balance inventory. Complete visibility prevents stockouts at one location while another has excess inventory.

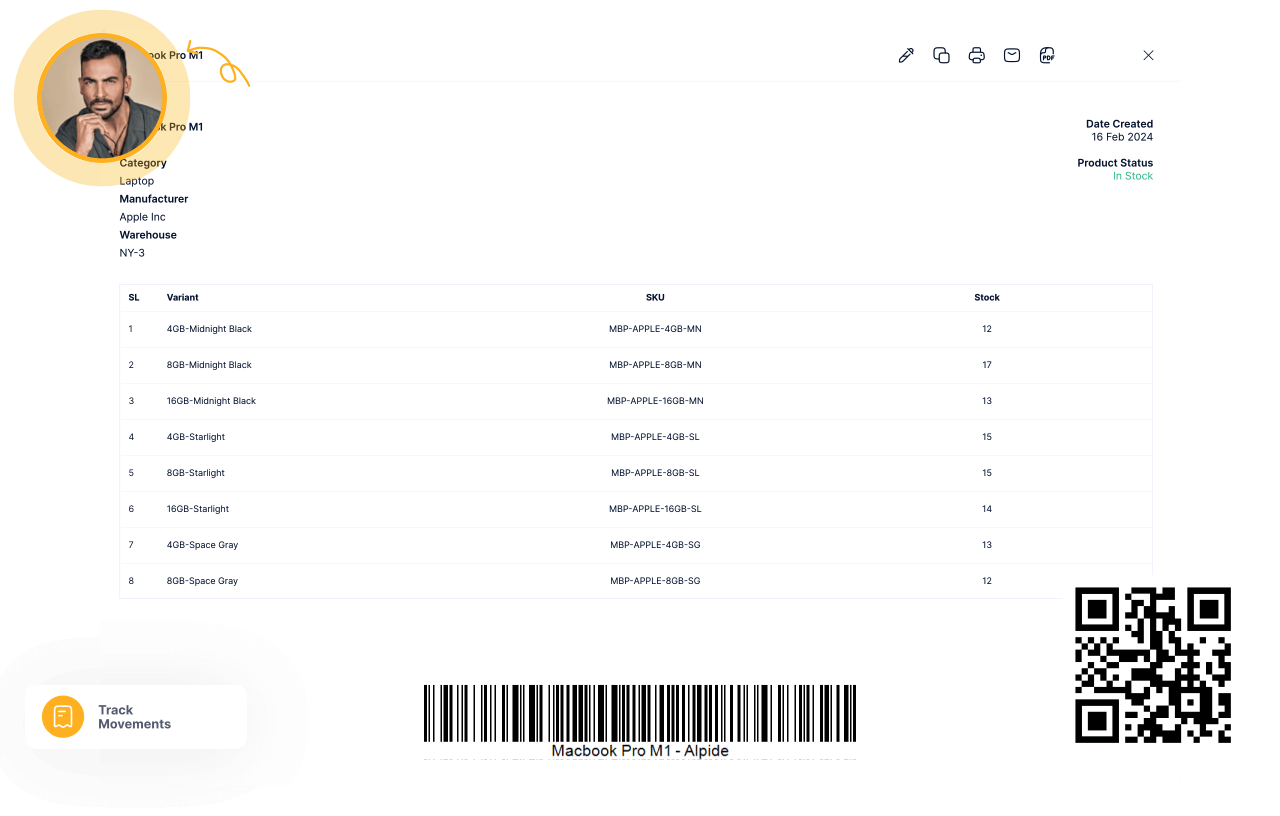

Lot and Serial Number Tracking

Track inventory using lot numbers, serial numbers, and expiration dates for complete traceability. During recalls, instantly identify affected lots and customers. Monitor expiration dates for perishable goods. Complete forward and backward traceability ensures regulatory compliance for pharmaceuticals, food products, electronics, and other regulated industries where product tracking is required.

Multi-Warehouse Inventory Management

Manage inventory across multiple warehouse locations with automated stock transfers, location-based fulfillment, and centralized visibility. Balance inventory between locations, route orders to nearest warehouse, and transfer stock to prevent stockouts.

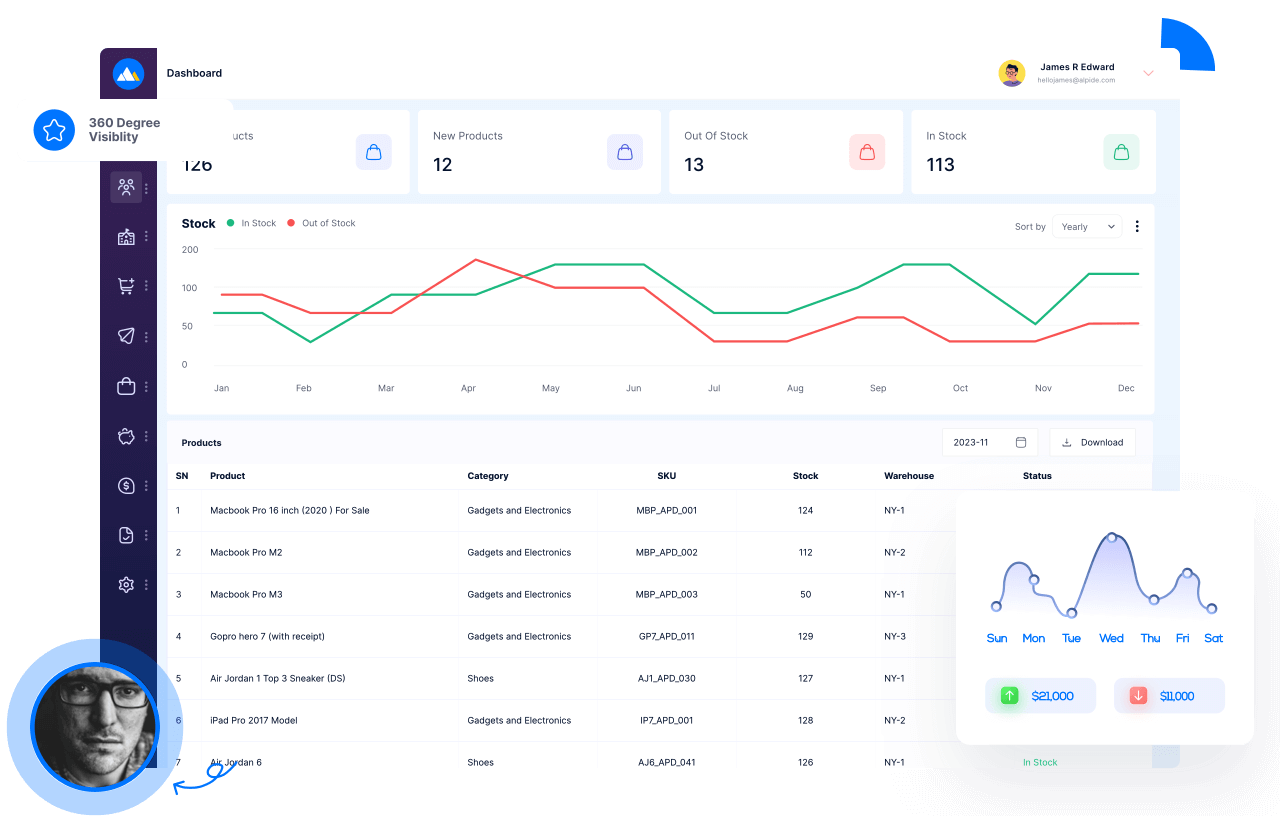

Inventory Valuation and Stock Level Analysis

See the total value of your inventory at cost and retail pricing. Track which products sell fastest versus slow-moving items tying up cash. Analyze stock levels to maintain optimal inventory—enough to fulfill orders without excess sitting on shelves.

Stock Transfer

Efficient inter-warehouse inventory movement to balance stock.

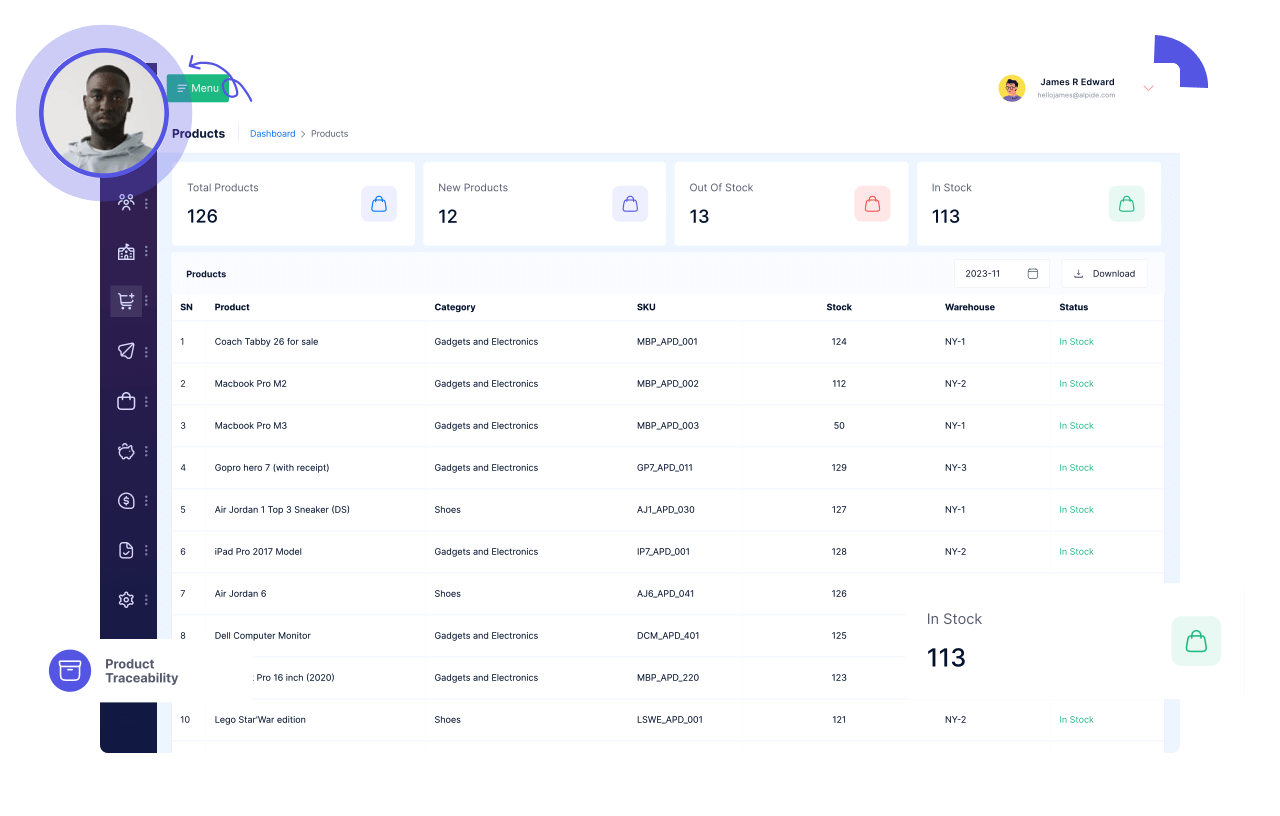

Product Management

Track products with lot and serial numbers for complete traceability. Manage expiration dates, batch tracking, warranty tracking, and recall management. Organize products using bin locations, SKU hierarchies, and unit of measure conversions.

Centralized Product Catalog Management

Maintain one product catalog that works across all locations and sales channels. Update product information, pricing, and descriptions once—changes apply everywhere automatically. Consistency across warehouses, stores, and online sales without duplicate data entry.

Price Management

Dynamic pricing strategies supported by real-time market data for competitive edge.

UOM Schema

Uniformity in operational workflow like tracking and monitoring the stock levels of products and services.

Barcode and QR Code Scanning

Generate barcodes or QR codes for every product to speed up receiving, transfers, picking, and shipping. Scan items instead of manual entry to eliminate errors and track exactly where products move throughout your business.

360 Degree Visibility

Centralized inventory dashboard shows stock levels, locations, aging, valuation, and movement history. Track slow-moving and aged inventory to identify obsolescence. Monitor warehouse performance metrics including turnover rates, accuracy, and fulfillment speed.

Manage Aged Slow-Moving Inventory

Innovative approaches to manage aged stock, reducing wastage and improving turnover.

Product Reporting

Insightful, detailed analytics on product lifecycle and health

Track Warehouse Performance 360

Comprehensive, real-time insights into warehouse operations efficiency

Tracking

Track inventory movement from receiving through shipping with lot and serial number traceability. Barcode scanning during receiving, transfers, and shipping ensures accuracy. Monitor inventory movement between warehouses, fulfillment performance, and product location history.

Fulfillment Tracking

Advanced tracking capabilities to monitor and optimize fulfillment processes in real-time.

Monitor Inventory Movement Between Warehouses

Monitor inventory movement between several warehouses to identify potential problems

Inventory Analysis

Comprehensive assessment tools to evaluate inventory health and optimize stock levels.

Product Traceability

Enhanced tracking of product movement to ensure quality and compliance.

Why Unified Inventory Management Beats Standalone Inventory Systems

Traditional businesses manage inventory using standalone inventory software, separate order management systems, disconnected warehouse software, and accounting that doesn't sync with inventory. Every sale requires manually updating inventory, every purchase needs manual inventory receipt entry, and stock counts never match between systems without constant reconciliation. Alpide Inventory Management connects directly with order management, purchasing, warehouse operations, manufacturing, and accounting in one unified platform. When orders ship, inventory reduces automatically and accounting entries post without manual input. When purchases arrive, inventory increases and accounts payable updates instantly. Manufacturing consumes raw materials and creates finished goods automatically. You eliminate duplicate inventory data entry across systems, stop reconciling inventory between warehouse and accounting, and end the frustration of overselling because systems don't sync. One system where inventory flows automatically from purchase to sale to financial reporting.

Common Inventory Scenarios Where Alpide Helps

Real-world challenges solved with unified inventory management platform.

Preventing stockouts while avoiding excess inventory

Set minimum and maximum stock levels for each product and location. System generates purchase requisitions automatically when inventory falls below reorder point. Demand forecasting based on sales history recommends optimal stock levels. Safety stock settings account for lead time variability. Automated reordering prevents stockouts without tying up cash in excess inventory.

Tracking inventory across multiple warehouse locations

View real-time inventory levels at each warehouse location from centralized dashboard. See which locations have stock available, which are low, and which have excess. Transfer inventory between locations to balance stock and reduce shipping costs. Route customer orders to nearest warehouse with available inventory for faster delivery and lower freight costs.

Managing expiration dates and lot tracking for recalls

Track lot numbers and expiration dates for every inventory receipt. System alerts when inventory is approaching expiration for clearance sales or disposal. During recalls, instantly identify which lots are affected, where they are located, and which customers received them. Complete forward and backward lot traceability ensures compliance and food safety.

Reconciling inventory counts between physical and system records

Conduct cycle counts by location, product category, or ABC classification without shutting down warehouse operations. Enter physical count quantities and system calculates variances automatically. Generate inventory adjustment documents to correct discrepancies. Track count accuracy by counter and location. Regular cycle counting maintains inventory accuracy without annual shutdowns.

Valuing inventory for financial reporting and tax purposes

Choose inventory valuation method including FIFO, LIFO, weighted average, or specific identification. System calculates inventory value automatically based on purchase costs and valuation method. Generate inventory valuation reports showing total inventory value by location, category, or product. Accurate inventory valuation ensures correct cost of goods sold and gross profit on financial statements.

Frequently Asked Questions

Can we set different reorder points for different warehouse locations?

Yes. Configure minimum stock levels, reorder points, and maximum stock levels individually for each warehouse location. High-volume warehouses maintain higher stock levels while smaller locations keep lower inventory. System generates purchase requisitions automatically when location-specific reorder points are reached. Transfer stock between locations when one warehouse is low and another has excess instead of purchasing more inventory.

How does lot and serial number tracking work for product recalls?

Every inventory receipt records lot number, serial number, and expiration date. System tracks which lot numbers were sold to which customers and when. During recalls, search by lot number to identify affected inventory still in stock and customers who received recalled items. Complete forward traceability shows where products went, backward traceability shows suppliers and receipt dates. Export recall data for regulatory compliance reporting.

Can we conduct cycle counts without shutting down warehouse operations?

Yes. Schedule cycle counts by location, product category, ABC classification, or specific products without halting operations. Warehouse staff count assigned items using mobile devices while other operations continue. Enter physical counts and system calculates variances automatically. Investigate and adjust significant discrepancies immediately. Regular cycle counting maintains 95%+ inventory accuracy without annual full physical inventories requiring warehouse shutdowns.

How do we track inventory movement between warehouse locations?

Create stock transfer orders to move inventory between locations. System reduces inventory at source location and increases at destination location automatically when transfer is confirmed. Track in-transit inventory during transfer period. View transfer history showing all movements between locations. Inter-warehouse transfers balance inventory distribution, reduce shipping costs by positioning stock closer to customers, and prevent stockouts at high-volume locations.

Can we track inventory costs using different valuation methods?

Yes. Choose FIFO (first-in-first-out), LIFO (last-in-first-out), weighted average, or specific identification valuation methods. System calculates inventory value automatically based on purchase costs and selected method. Different valuation methods affect cost of goods sold, gross profit, and ending inventory value on financial statements. Generate inventory valuation reports showing total value by location, category, and product for financial reporting and tax purposes.

How does the system handle inventory for products with multiple units of measure?

Define unit of measure conversions for products sold in different quantities like eaches, cases, and pallets. System converts automatically between units when receiving, selling, or transferring. Purchase in cases, store in eaches, sell in boxes with automatic conversion. Track inventory in base unit while displaying in appropriate unit for each transaction. Multi-UOM support eliminates conversion errors and simplifies inventory management for products packaged multiple ways.

Can we reserve inventory for specific customers or sales orders?

Yes. Sales orders reserve inventory automatically when created, reducing available quantities for other orders. View reserved versus available inventory separately. Priority customers or large orders can reserve inventory in advance of shipment date. Unreleased inventory becomes available if orders are cancelled or modified. Inventory reservation prevents overselling, ensures high-priority orders ship on time, and provides accurate available-to-promise quantities for new orders.

What reports help identify slow-moving or obsolete inventory?

Inventory aging reports show how long items have been in stock by 30/60/90/180+ day buckets. Inventory turnover reports identify products with low sales relative to stock levels. ABC analysis categorizes products by sales volume to focus attention on highest-value items. Slow-moving inventory reports flag products without sales activity in specified timeframe. These reports help identify obsolete inventory for clearance sales or disposal before it consumes warehouse space and working capital.

How is Alpide Inventory Management different from standalone inventory software like Fishbowl or Cin7?

Fishbowl and Cin7 are dedicated inventory platforms requiring integration with order management, warehouse operations, and accounting systems. Alpide Inventory Management integrates natively with sales orders, purchase orders, manufacturing, warehouse management, and accounting in one unified platform. For growing businesses needing complete operations management beyond just inventory tracking, Alpide eliminates integration complexity, data synchronization delays, and costs substantially less than buying separate systems.

Related Questions About Inventory Management Software

Do we need barcode scanners for inventory management?

Barcode scanning dramatically improves inventory accuracy but is not required. Manual entry works for low-volume operations. As order volume increases, barcode scanning during receiving and shipping reduces errors from 5-10% with manual entry to under 1%. Mobile devices with camera scanning provide affordable barcode capability without dedicated scanners.

How often should we conduct physical inventory counts?

Annual full physical inventory counts are outdated. Modern approach uses continuous cycle counting where a portion of inventory is counted weekly. High-value A items counted monthly, medium-value B items counted quarterly, low-value C items counted annually. Cycle counting maintains accuracy without shutting down operations and identifies problems immediately rather than once per year.

Can inventory management software integrate with our existing accounting system?

Alpide includes integrated accounting eliminating need for separate accounting software. For businesses committed to existing accounting systems, work with Alpide team to discuss integration options. Integrated inventory and accounting in one system eliminates reconciliation headaches, ensures real-time financial accuracy, and reduces monthly closing time significantly versus separate systems.

What's the ROI of implementing inventory management software?

Typical ROI includes reduced stockouts increasing sales by 5-10%, reduced excess inventory freeing up 15-25% of working capital, eliminated manual counting saving 10-20 hours weekly, reduced inventory shrinkage from better accuracy, and faster order fulfillment improving customer satisfaction. Most organizations achieve payback within 6-9 months from inventory reduction and labor savings alone.

Alpide blog

Boost Your Business with Alpide! Expert insights on ERP, E-Commerce, CRM, Warehouse, Accounting, HR, Sales, Finance & more to fuel your growth.

Talk to Expert

Transform Your Business With Alpide

Streamline your business operations, access real-time insights, enhance control, ensure data accuracy, lower expenses, fulfill orders efficiently, and elevate customer service with.

Contact Us