- Product Engineering -

Engineer Products with Precision

Multi-level BOMs, intelligent routings, and complete product specifications that drive your entire manufacturing operation. Stop struggling with Excel BOMs that break, get lost, or exist in multiple versions.

Complete BOM Component Library

Alpide supports every type of component you need in your BOMs. From core materials to phantom assemblies, manage every aspect of your product structure with precision and control.

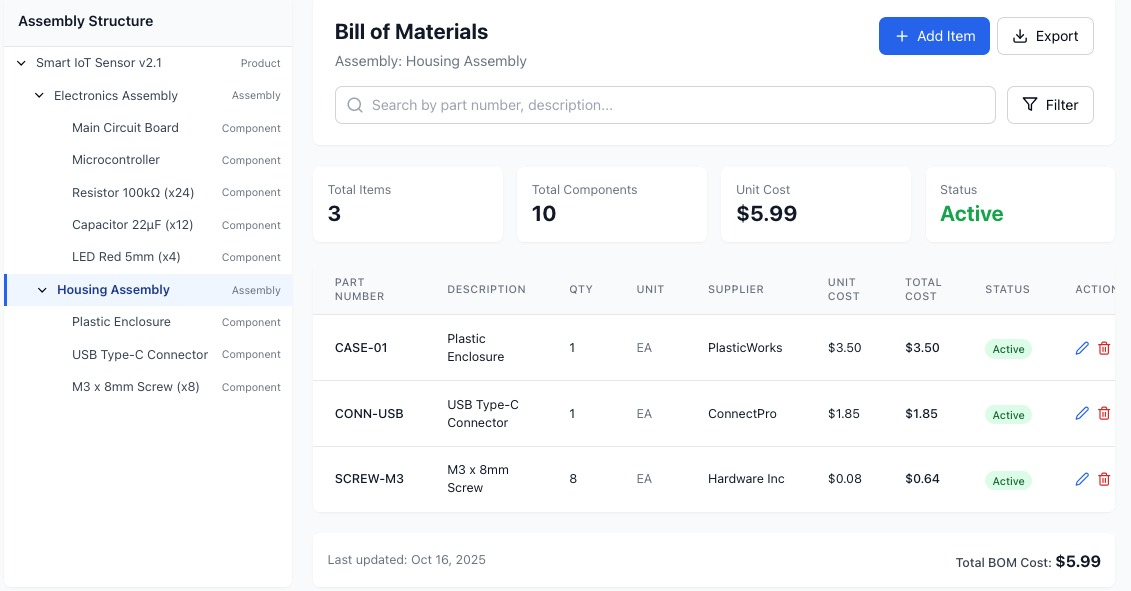

Visual BOM Management

Alpide gives you visual BOM management with unlimited hierarchy depth, automatic cost roll-up, variant configuration, and complete change control. No more Excel BOMs that break or get lost.

Intelligent Routing System

Define complete manufacturing routings with operations, work centers, and lead times. Track setup and run times, lot sizes, and yield factors for accurate production planning.

Bill of Materials (BOM)

The foundation of manufacturing. Define what goes into your products with unlimited depth, automatic cost calculations, and complete traceability.

Visual Tree Navigation

Navigate complex BOM structures with intuitive visual tree interface for easy management.

Multi-level Cost Roll-up

Product costs calculate automatically. Change a component cost - parent updates instantly.

Version Control

Track every change with Engineering Change Orders, approval workflows, and complete audit trails.

Where-Used Reporting

See instantly which products use any component. Critical for change impact analysis.

Sub-Assembly

Internally manufactured components that have their own BOM and routing. Built in-house from materials and purchased parts.

Multi-level BOM Structure

Each sub-assembly has its own complete BOM structure with components and sub-components.

Complete Routing

Define complete manufacturing routing with all operations and work centers.

Work Center Assignment

Assign specific work centers and lead times for production planning.

Setup and Run Time

Track setup time and run time per unit for accurate production scheduling.

Lot Size and Yield

Define lot sizes and yield factors for efficient production planning.

Purchased Part

Ready-to-use components bought from external suppliers. No internal manufacturing needed.

Supplier Management

Manage primary and alternate suppliers with supplier-specific part numbers.

Cost and Pricing

Track unit costs, price breaks, and supplier lead times for MRP planning.

Order Quantities

Set minimum order quantities and economic order quantities for optimal purchasing.

Quality Documentation

Maintain certificates of conformance and quality documentation for purchased parts.

Phantom Assembly

Logical groupings that do not physically exist as stocked items. Used for kitting instructions and organizing components.

Logical Grouping

Organize components logically without creating physical inventory items.

Cost Pass-through

Costs pass through to parent assemblies without intermediate inventory tracking.

Work Instructions

Simplify work instructions by grouping related components together.

MRP Explosion

MRP explodes phantom assemblies to actual parts for production planning.

No Inventory Impact

No inventory transactions - purely logical for organization and planning.

Reference Item

Non-stock documentation and reference materials. No inventory impact, just information for operators.

Assembly instructions

Manage assembly instructions with version control, approval workflows, and complete audit trails.

Labels and decals

Labels and decals for products.

Software versions

Software versions for products.

Calibration certificates

Calibration certificates for products.

External documentation

Other external documentation for products.

Alpide blog

Boost Your Business with Alpide! Expert insights on ERP, E-Commerce, CRM, Warehouse, Accounting, HR, Sales, Finance & more to fuel your growth.

Stop Managing BOMs in Spreadsheets

See how Alpide visual BOM navigator handles unlimited complexity with ease

Talk to Expert

Transform Your Business With Alpide

Streamline your business operations, access real-time insights, enhance control, ensure data accuracy, lower expenses, fulfill orders efficiently, and elevate customer service with.

Contact Us