- Shop Floor Control -

Shop Floor Control Software for Real-Time Production Tracking

Track production progress, labor time, and material consumption in real-time from tablets and mobile devices. See exactly what's happening on your factory floor right now. Eliminate walking the floor with clipboards and waiting until tomorrow to see yesterday's production numbers.

Managing shop floor operations with paper clipboards and end-of-shift reports means discovering problems hours after they occur. Production delays, quality issues, and material shortages remain invisible until it's too late to fix them. Alpide Shop Floor Control gives you instant visibility into every work order, operator, and production station so you catch problems immediately and make decisions based on what's actually happening right now.

Complete Shop Floor Visibility

Four integrated views give you complete control of your production floor. Real-time visibility into every work order, every operator, and every production station. See what's happening right now without walking the floor or waiting for shift reports.

Real-Time Production Monitoring

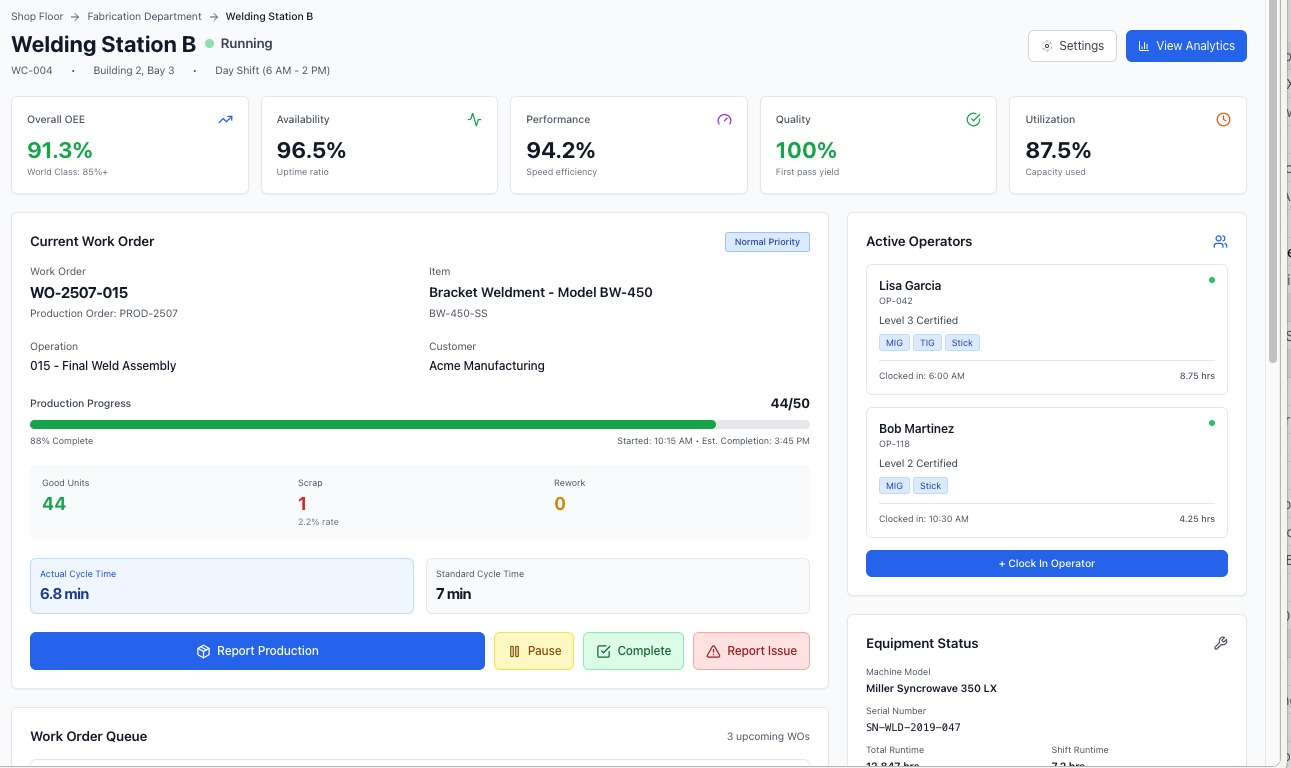

See live information about every work order, operator, and production station. View everything happening right now on one screen with real-time performance metrics and instant alerts when problems occur.

Mobile Access for Shop Floor Teams

Operators work on the factory floor, not at desks. The system works on tablets and smartphones at production stations with large touch-friendly buttons and instant data updates that sync immediately to manager dashboards.

Shop Floor Dashboard

Your command center. See everything happening right now on one screen.

Live Progress Tracking

Track production progress in real-time with live updates on work order completion, operator efficiency, and material consumption.

Alert Management

Get instant alerts for material shortages, quality issues, and production bottlenecks before they impact operations.

Performance Monitoring

Monitor efficiency by production station and operator performance in real-time for immediate insights.

Production Station Monitoring

Monitor each production station individually. See equipment utilization, current operations, waiting job queues, and assigned operators for every station on your factory floor.

Station Status View

Current work order and operation running, queue of jobs waiting to start, utilization percentage showing how busy the station is, assigned operators working at this station.

Equipment Utilization

Track production station utilization in real-time. Example: CNC Machining at 115% capacity, Welding at 92% capacity.

Queue Management

Monitor queue of waiting jobs and optimize production station scheduling for maximum efficiency.

Operator Assignment

Track assigned operators for each production station and manage labor allocation effectively.

Labor Tracking

Track who is working on what, for how long, and how efficiently.

Labor Features

Clock in and out tracking, time tracking by work order, efficiency calculations comparing actual versus standard time, multiple workers per work order, labor cost tracking, operator performance reports.

Time Tracking

Accurate time tracking by work order with automatic efficiency calculations comparing actual vs standard times.

Performance Reports

Generate operator performance reports with efficiency metrics and labor cost analysis.

Multi-Worker Support

Support multiple workers per work order with individual time tracking and performance monitoring.

Material Consumption

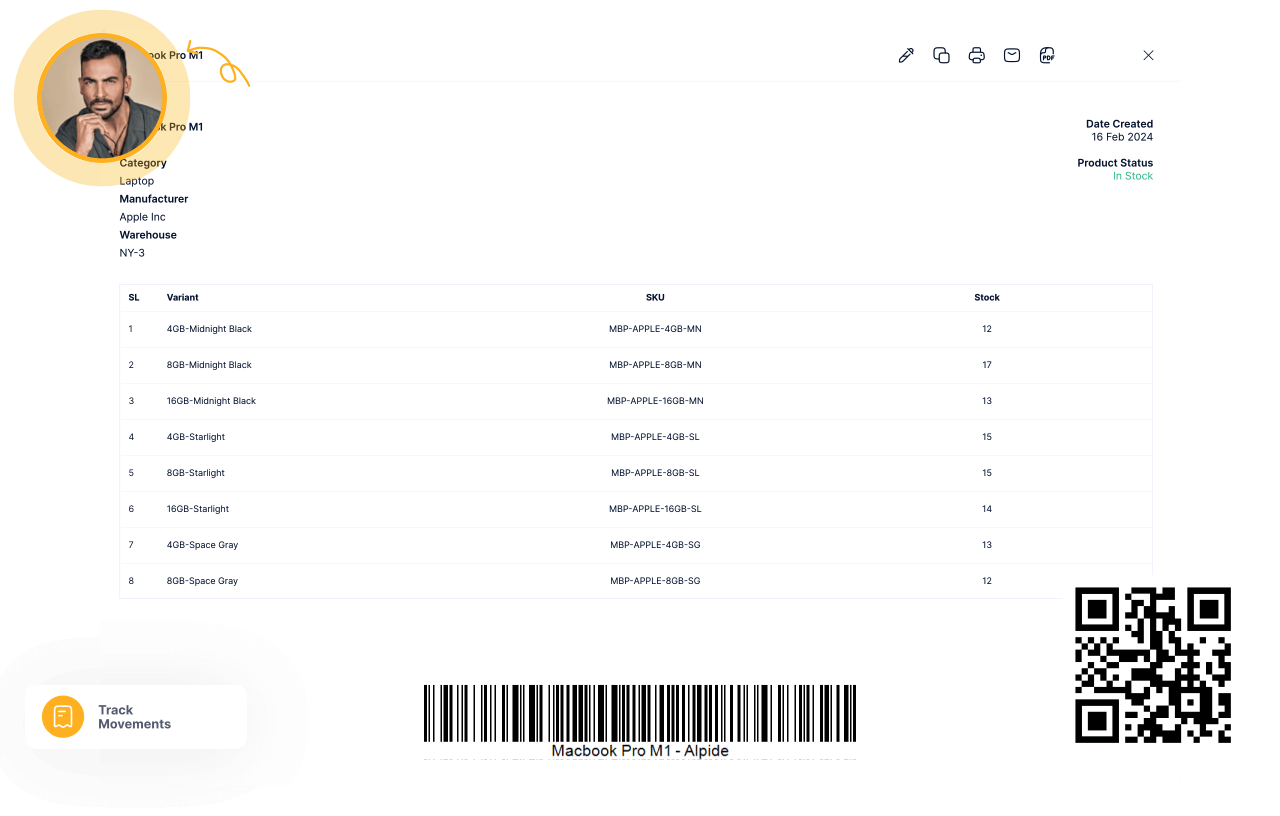

Track material issues and consumption in real-time. Know inventory status instantly.

Material Tracking

Material issues to work orders, real-time inventory reduction, automatic material consumption recording, material returns and adjustments, shortage alerts, scrap and waste tracking.

Real-Time Inventory

Real-time inventory reduction as materials are consumed with instant updates to inventory levels.

Shortage Alerts

Get instant alerts for material shortages before they impact production schedules.

Scrap Tracking

Track scrap and waste in real-time with detailed reporting and analysis capabilities.

Why Real-Time Visibility Matters

Faster Decisions

See problems as they happen. Make decisions based on current data, not yesterday's numbers.

Catch Issues Early

Identify bottlenecks, quality problems, and material shortages before they stop production.

Better Performance

Transparency drives accountability. Operators see their efficiency and strive to improve.

Alpide blog

Boost Your Business with Alpide! Expert insights on ERP, E-Commerce, CRM, Warehouse, Accounting, HR, Sales, Finance & more to fuel your growth.

Why Unified Shop Floor Control Beats Separate Systems

Traditional shop floor operations use paper travelers, separate time clocks, manual material requisitions, and end-of-shift production reports. Each requires manual data entry into different systems with hours or days of delay before information reaches planning and accounting. Alpide Shop Floor Control unifies production tracking, labor time, material consumption, and quality reporting in one real-time system. When operators report production, inventory decreases instantly. When labor is recorded, costs update automatically. When quality issues occur, production and planning see problems immediately. Shop floor, planning, inventory, and accounting all work from identical current data. You eliminate manual paperwork, data entry delays, and decisions based on outdated information. One modern system replaces scattered paper systems and disconnected tracking.

Common Shop Floor Scenarios Where Alpide Helps

Real-world challenges solved with real-time shop floor visibility and mobile reporting.

Identifying Production Bottlenecks in Real-Time

See which production stations are overloaded and which have capacity available right now. Monitor queue lengths showing jobs waiting at each station. Reassign work or adjust schedules immediately when bottlenecks develop instead of discovering capacity problems at the end of the shift.

Catching Quality Issues Before Shipping Defective Products

Operators flag quality problems immediately when discovered during production. Supervisors see alerts instantly and can stop work orders before producing more defective units. Prevent entire batches from being scrapped because one operator noticed an issue early.

Tracking Actual Labor Costs for Job Costing

Record actual time spent on each work order as operators clock in and out of jobs. Compare actual labor hours versus estimated time to identify jobs running over budget. Calculate accurate job profitability using real labor costs instead of estimates.

Preventing Material Shortages from Stopping Production

See material shortages immediately when operators report running low instead of waiting until lines shut down. Alert purchasing and inventory teams in real-time so they can expedite deliveries or find alternate materials before production stops completely.

Providing Customers with Accurate Order Status

Check real-time production progress when customers call asking about order status. See exactly which operations are complete, what's currently in progress, and estimated completion time. Provide accurate delivery updates based on actual factory floor status instead of guessing.

See Your Shop Floor in Real-Time

Stop walking the floor with clipboards. Get live visibility from anywhere with mobile shop floor control.

Frequently Asked Questions

How does real-time shop floor tracking work?

Operators use tablets, smartphones, or terminals at their production stations to report activities as they happen. They clock into work orders, report completed quantities, record materials consumed, and flag quality issues. The system updates instantly so supervisors, planners, and managers see production status in real-time. Instead of waiting for end-of-shift reports, everyone sees current factory floor status immediately including which jobs are running, completed quantities, and any problems occurring.

Can shop floor control software work on mobile devices and tablets?

Yes, modern shop floor control software works on tablets and smartphones at production stations. Large touch-friendly buttons accommodate workers wearing gloves. Responsive design adapts to different screen sizes from phones to wall-mounted tablets. Data syncs instantly to manager dashboards when operators report production. Workers don't need to leave their stations or wait for computers—they use mobile devices right at their workstations for immediate reporting.

How does shop floor control help identify production bottlenecks?

The software shows utilization levels at each production station in real-time, which stations are overloaded and which have available capacity. Queue lengths show jobs waiting at each station. When one station runs at 130% capacity while others sit at 60%, you immediately see the bottleneck. Supervisors can reassign work, adjust schedules, or add resources to constrained stations before delays propagate through the entire production schedule.

Can operators report quality issues directly from the shop floor?

Yes, operators flag quality problems immediately when discovered during production using mobile devices at their stations. They record defect types, affected quantities, and problem descriptions with photos if needed. Supervisors receive instant alerts and can stop work orders before producing more defective units. Quality teams see issues in real-time and can investigate root causes immediately instead of discovering problems days later during final inspection.

How does shop floor control track labor time and costs?

Workers clock in and out of specific work orders at production stations. The system tracks actual time spent on each job, multiple workers on the same order, and efficiency comparing actual versus estimated time. Labor costs calculate automatically using actual hours and worker pay rates. You see accurate job costs for profitability analysis instead of using estimated labor. Track operator efficiency and identify training needs from actual performance data.

How does material consumption tracking work in shop floor control?

Operators record materials consumed during production either manually or through barcode scanning at production stations. Inventory decreases instantly when materials are issued to work orders. The system alerts when materials are running low before complete shortages stop production. Track scrap and waste separately from good production. Material consumption data flows automatically to inventory management and accounting without separate data entry or reconciliation.

Can shop floor control software integrate with production planning systems?

Yes, shop floor control integrates with production planning to show which jobs are scheduled, when they should start, and required materials. As operators report production progress, planning sees actual completion status and can adjust schedules if jobs run ahead or behind. Capacity planning uses real utilization data from the shop floor. Material planning sees actual consumption rates. All systems work from identical current production data.

How quickly can operators learn to use shop floor control software?

Mobile-first shop floor interfaces are designed for simplicity with large buttons, intuitive workflows, and minimal steps to report production. Most operators learn basic functions—clocking in, reporting quantities, and flagging issues—in under 30 minutes of training. Touch-friendly design works for operators wearing gloves or with limited computer experience. The system guides workers through reporting steps reducing errors and eliminating confusion about what to enter.

How is Alpide Shop Floor Control different from NetSuite or Dynamics 365 for production tracking?

NetSuite and Dynamics 365 provide shop floor tracking with features like digital work instructions, equipment integration, and production analytics. Alpide's advantage is shop floor control that works seamlessly with the entire manufacturing system—production data updates planning, material consumption adjusts inventory instantly, and labor time flows to accounting in real-time. For growing manufacturers needing shop floor visibility that actually connects with daily operations, Alpide eliminates delays between production floor and business systems at substantially lower cost.

Related Questions About Shop Floor Control

Talk to Expert

Transform Your Business With Alpide

Streamline your business operations, access real-time insights, enhance control, ensure data accuracy, lower expenses, fulfill orders efficiently, and elevate customer service with.

Contact Us